Allied Plastics has taken an important step in cementing its leadership status with respect to the environment.

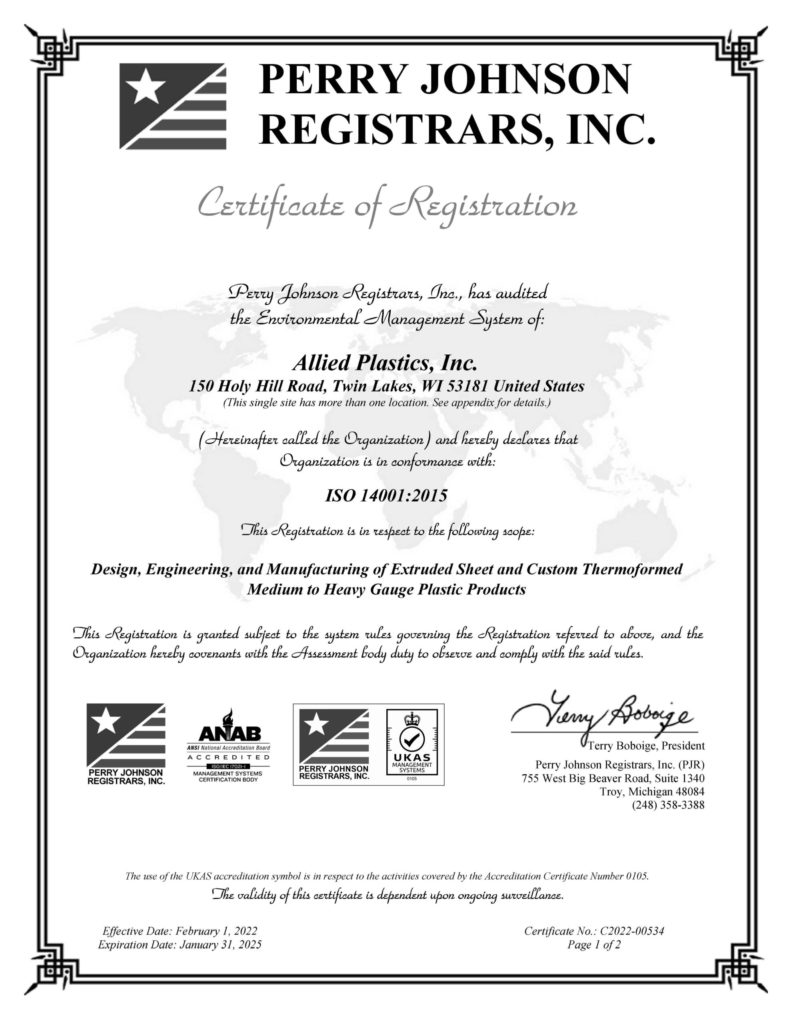

The company recently earned ISO 14001 certification, which sets criteria for a robust environmental management system.

Companies meeting this standard can feel confident in their ability to reduce waste and use resources efficiently, and overall lessen their environmental footprint on a continual basis.

Allied Plastics’ customers also gain some assurances.

“Achieving this certification is a win-win for both Allied Plastics and our customers,” says Jon Larson, OEM sales manager at Allied Plastics. “If we are recycling materials more and reducing waste, that translates into cost savings for our customers.”

Customers can also benefit from improved quality assurance through more in-house processing of materials. Furthermore, due to less reliance on outside vendors, material fallout is reduced, production can happen faster and delivery times can be reduced.

Formalized commitment enables continuous improvement

A lot of what Allied Plastics needed to do to achieve ISO 14001 status was already being done for many years. By making the commitment to formalize their environmentally friendly operations through this standard, the company is now better positioned to continually improve.

“ISO 14001 started to become a conversation piece in 2019 when we were talking about the future and how our business wanted to evolve,” says Eric Saunders, quality manager at Allied Plastics. “We decided to go for it in 2021. A lot of the documentation in our system has been aligned with the 14001 standard for the better part of a decade. It was actually rather difficult for the ISO auditors to audit our system because we were already so far advanced in this area.”

For example, Allied’s manufacturing equipment is electric-powered, resulting in zero carbon emissions. Additionally, as mentioned earlier, Allied Plastics has been repurposing most of its materials for several years.

“When we started extruding our own sheets, that gave us additional recycling materials for our repurposing processes,” Saunders explains. “Most of our processing generates very little waste. All of our materials that are byproducts, such as trim scrap are collected, recycled, and repurposed back into the system.”

Achieving ISO 14001 certification now inspires Allied Plastics to continue striving for new goals. One new area for improvement relates to the maintenance of manufacturing equipment, something that isn’t covered in the ISO 9001 standard. Allied Plastics is now developing processes for the handling of waste oil stemming from the lubes used to maintain its equipment.

“In the past, we stored the used oil in large containers and kept them in a storage building,” Saunders says. “We gave that oil to local shops that used it in their waste oil heaters. That really wasn’t efficient, though. Our operation doesn’t consume a lot of lubricating oil; we order one 55-gallon drum every few months or so. Still, we were generating waste oil faster than the shops were needing it. So now we’ve identified the need for more controlled processes regarding the management of these lubricating oils.”

Allied Plastics and its customers will benefit in two ways. First, better processes will result in stricter and more streamlined preventive maintenance, which helps ensure that manufacturing equipment remains in tiptop shape. Secondly, the possibility of an environmental mishap is greatly reduced.

Allied Plastics is now capping the amount of oil kept on its property. Saunders has developed a process to follow, which includes the necessary steps to remove any materials not being used. “We’re also looking into how we could build our own containment basins for the oil to be stored in,” Saunders points out. “We’ve also reached out to a recycling company to establish a program where they will come and remove the oil on a regular basis.”

Another unique component to ISO 14001 relates to risk management. From an environmental standpoint, hazardous material spills do present a risk. Allied Plastics is now taking an even harder look at certain HR processes related to material handling to ensure that drivers have the skills, training and credentials necessary to perform the job safely.

Going forward, integrated ISO 14001 and 9001 audits will take place annually at Allied Plastics. In the meantime, internal audits will ensure that everything is staying on course and that employees remain focused on the company’s environmental footprint.

“We already have some customers that are requiring their suppliers to be ISO 14001 certified,” Larson points out. “Other customers don’t require it, but see a lot of value in it. This is another box we can check when building a relationship with a customer.”

“I have a strong feeling that ISO 14001 is going to become a requirement across the board in the not too distant future,” Saunders adds. “Right now, it’s just a recommendation. But we’ve decided to do it because it will help us take our efficiency and environmental management systems to another level, which benefits both us and our customers.”