Innovative Vacuum Thermoforming Services for Durable Plastic Solutions

Thermoforming

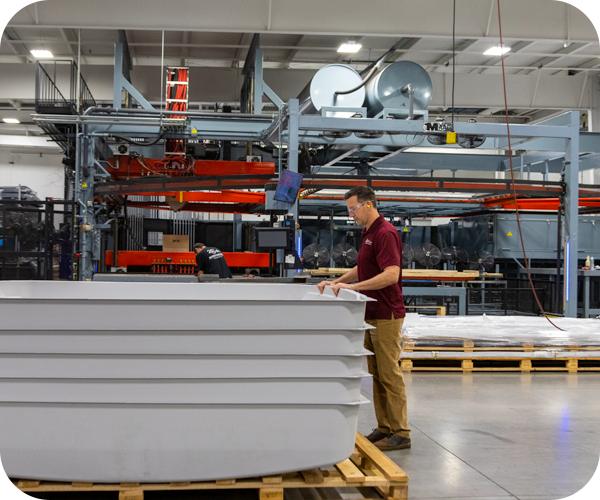

Custom Thermoforming Solutions for Your Application

Allied Plastics is a full service custom plastic thermoformer specializing in medium to heavy gauge quality thermoplastic parts with quick turnarounds. We supply custom single sheet, twin sheet and pressure formed plastic products to a wide variety of OEM companies.

PLASTIC EXTRUSION

PLASTIC SHEET EXTRUSION

To support our thermforming process, Allied Plastics also offers in-house plastic sheet extrusion in material types such as HMWPE, HDPE, TPO, ABS, and Styrene. We can produce sheet sizes up to 120” wide and .550” thick in smooth, haircell, or levant textures.

INDUSTRIAL PACKAGING

INDUSTRIAL PACKAGING

Allied Plastics are experts in high quality Vacuum Formed and Twin Sheet reusable/returnable Industrial Packaging and Dunnage. Our accomplished, knowledgeable staff has experience in virtually every material-handling situation. Our engineers can take your part, prints or CAD files and design a custom Vacuum Formed Plastic reusable packaging tray, lid, or pallet that will protect your parts.

Retail Ready

Finishing & Assembly

If your thermoformed part needs hardware installed, adhesives added, or parts assembled, our highly skilled production team can integrate these items before shipment.