Logistics are changing faster and carrying more demands than ever before. In some cases, standard wooden or plastic pallets can’t keep up. That’s where thermoformed customized pallets come in.

These pallets are designed to precisely fit your products. As a result, they can reduce damage, speed up handling, and streamline shipping. On top of that, they’re strong and lightweight, meaning they’re built with modern logistics in mind. Below, we’re exploring what thermoformed pallets are and if they’re right for your business.

What Are Thermoformed Pallets?

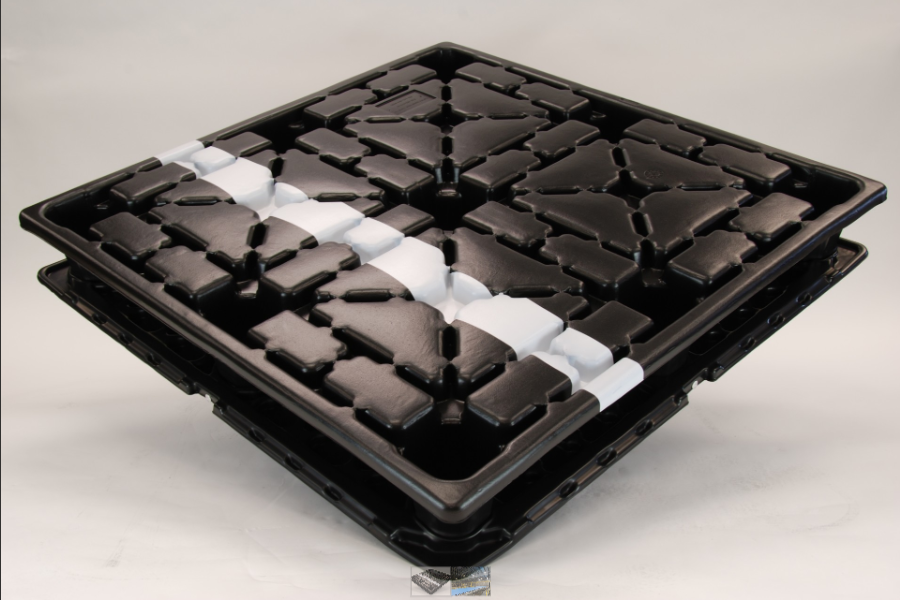

As mentioned above, thermoformed pallets are durable, lightweight pallets that are used for a wide range of applications. These pallets are created by heating a plastic sheet until it’s pliable, then molding it into a specific shape by draping it over a mold. From there, it’s cooled and trimmed to create the finished product. This process creates a strong, moisture-resistant pallet with a longer lifespan than wooden options.

They’re often chosen for industries like pharmaceuticals, food and beverage, and automotive due to their hygienic properties and ability to withstand various conditions. They can often be made out of a wide range of materials, giving you full control over the final product. These materials might include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), acrylic (PMMA), and polystyrene (PS).

Advantages of Customized Thermoformed Plastics

Thermformed pallets give businesses a wide range of benefits. From better protection to a higher ROI, there’s a reason why so many companies opt for this solution.

Precision Fit

Many businesses choose thermoformed pallets because they can be made with tight tolerances. This means they can be designed to match the exact dimensions of a product. Overall, they minimize shifting during transport and better protect the products. This can improve your bottom line by reducing the risk of costly returns.

Durability and Strength

As mentioned above, plastic pallets can be more durable than traditional alternatives. They’re better equipped to resist moisture, chemicals, and impacts. Additionally, they do not harbor pests or bacteria, making them a good choice for industries where hygiene is a big concern. When companies need an option that can deliver consistent performance, they turn to plastic.

Lightweight Design

With shipping and logistics costs rising, plastic pallets are an easy way to reduce expenses. While they might be more expensive to produce, their ROI can be better than wooden options. Lighter pallets are easier to handle and move, and help lower freight costs by reducing overall shipping weight.

Cost-Efficiency Over Time

A customized pallet doesn’t just provide savings in shipping costs. Their durability means that fewer replacements are needed. Additionally, the protection they provide can reduce product loss. For many businesses, the combination of strength, longevity, and efficiency makes them a smart investment.

Trust Allied Plastics for High-Quality Thermoformed Pallets

If you’re in need of quality customized pallets, turn to Allied Plastics. For the last 30 years, we’ve been providing advanced thermoforming solutions to companies in a range of industries. We specialize in twin sheet forming, single sheet forming, drape forming, pressure forming, and sheet over sheet forming capabilities. With advanced machinery and short lead times, we’re ready to take on your next project.

When you work with us, you know you’re getting a high-quality product. Our team can handle your entire project from start to finish. We maintain rigorous quality assurance processes and maintain an ISO 9001:2015 certification to ensure high-grade products. Trust us to deliver components that meet your exact needs, at a competitive price.

Let’s Get Started

Want to learn more about what we can do for you? Reach out to our team for an initial consultation.