The Complete Journey from Concept to Finished Component

Transforming raw plastic into precision-engineered components doesn’t happen by chance. Behind every durable agricultural panel, perfectly fitted automotive part, or robust industrial container lies a sophisticated fabrication process that combines material science, engineering expertise, and advanced manufacturing technology. For manufacturers seeking competitive advantages, understanding the interconnected stages of the plastic fabrication process reveals opportunities for quality improvements, cost efficiencies, and enhanced product performance.

Want expert guidance on optimizing your plastic fabrication process? Reach out to our engineering team today.

The Engineering Foundation: Design for Manufacturability

The fabrication journey begins long before the first piece of plastic is formed. At Allied Plastics, our engineering team uses advanced ProEngineer 3D software to develop designs optimized specifically for the thermoforming process. This critical first step considers wall thickness distribution, draft angles, corner radii, and material flow patterns — elements that determine both formability and final performance characteristics.

Unlike generic plastic design, fabrication-focused engineering anticipates downstream production requirements, preventing costly modifications later in the process. This integrated approach ensures components meet both functional requirements and manufacturing efficiency standards.

Material Innovation: Custom Extrusion Capabilities

The selection and preparation of material represents a pivotal fabrication stage that directly impacts product quality. Allied Plastics’ vertical integration includes in-house sheet extrusion capabilities for materials up to 120″ wide and 200″ long, with thicknesses ranging from .060″ to .550″.

This control over the extrusion process allows for:

- Custom material formulations optimized for specific applications

- Multi-layer co-extrusion combining different performance characteristics

- Precise control over material properties like impact resistance and UV stability

- Various texture options (smooth, haircell, or levant) are incorporated during extrusion

By managing this critical fabrication stage in-house, we eliminate variables that can compromise final product quality while enhancing material performance for specific applications.

Forming Excellence: Specialized Thermoforming

The primary forming stage transforms flat plastic sheets into three-dimensional components using carefully controlled heat, pressure, and cooling cycles. Allied Plastics specializes in heavy-gauge thermoforming with capabilities that include:

- Single sheet vacuum forming for cost-effective, large components

- Twin sheet forming for hollow, structural parts with complex geometries

- Pressure forming for enhanced detail and deeper draws

Our facility houses over 20 advanced thermoforming machines capable of handling substantial parts—up to 9′ x 14′ with draw depths reaching 60″. This specialized expertise ensures optimal material distribution, minimized stress concentrations, and consistent dimensional accuracy across production runs.

Precision Finishing: Completing the Plastic Fabrication Process

The fabrication journey continues with critical finishing operations that transform formed parts into ready-to-use components. Allied’s comprehensive capabilities include:

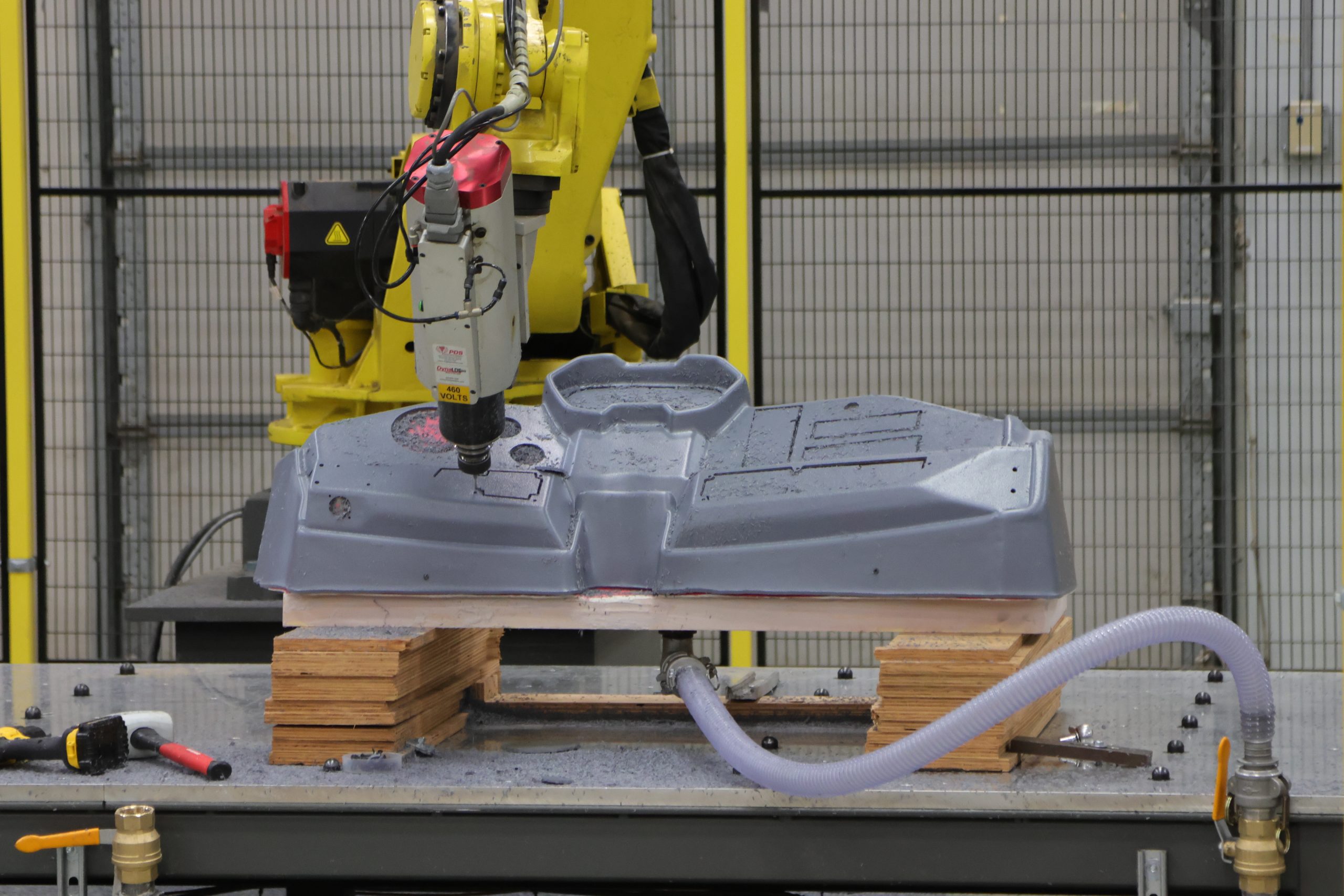

- Precision trimming using twelve 5-axis CNC machines and five robotic systems

- Hardware installation and assembly integration

- Custom adhesive bonding for multi-material applications

- Final quality verification and testing

This integrated approach eliminates multiple handoffs between vendors, reducing both lead times and quality risks while ensuring consistent results.

The Allied Advantage: Vertically Integrated Plastic Fabrication

The plastic fabrication process presents numerous decision points that influence cost, quality, and performance outcomes. Allied Plastics’ vertically integrated approach provides comprehensive control over each fabrication stage, from initial design through final assembly. This integration enables us to maintain tight quality controls while optimizing the entire process for efficiency.

With more than 30 years of specialized thermoforming experience and a 210,000-sq.-ft. manufacturing facility in Twin Lakes, Wisconsin, Allied Plastics delivers complete fabrication solutions for the most demanding applications. Our expertise spans diverse industries including agricultural equipment, automotive components, and industrial packaging.

Contact our team today to discuss how our comprehensive plastic fabrication capabilities can support your specific manufacturing needs.