25th year of business begins

June 2019 Allied installs CNC #8 a 5×5 twin table 5 axis cnc with a 48” Z height

August 2019 Allied installs its 14th thermoforming machine a 6’ x 12’ single station thermoformer.

August 2019 Allied purchases 2- 50hp rotary screw air compressors for additional capacity.

September 2019 Allied purchases old recycling center property from Village of Twin Lakes for additional parking of semi-trailers.

October 2019 Allied purchases second 6” extrusion line 78” wide.

December 2019 Allied adds a 3rd 2.5” co-ex extruder on it 132” Extrusion Line..

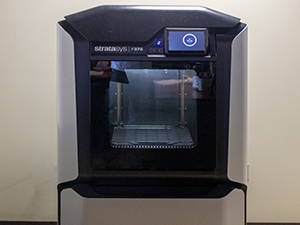

December 2019 Allied purchases its first 3D printing machine for the engineering department for rapid prototyping.

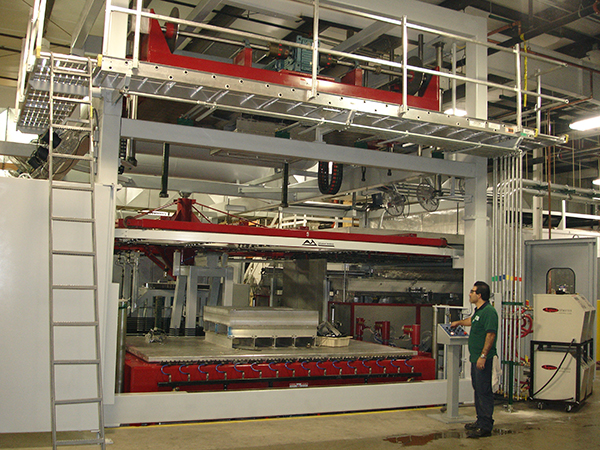

December 2019 Allied purchased a CNC Milling machine for the pattern shop and metal fabrication departments.

April 2018 Allied purchases semi-truck and custom wrap for 53’ trailer

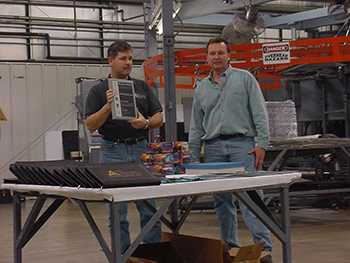

October 2018 Allied hosts an open house for the Society of Plastics Engineers, Chicago & Milwaukee chapters.

April 2017 Allied purchases its 12th thermoforming machine. Brown 5×7 three station rotary.

May 2017 Allied purchases is 13th thermoforming machine. Brown 4×6 three station rotary.

May 2017 Allied erects four sixty foot silos that will hold re-grind and virgin pellets for the new extruder.

June 2017 Allied installs their first sheet extrusion line.

March 2016 Allied has local farmer park a John Deere tractor on premises to help show part applications to employees.

August 2016 Allied completes Construction of the new engineering center and names it the “IDEA” center which stands for “Innovation, Design, Engineering, Application”

September 2016 Speaker of the House, Congressman Paul Ryan visits Allied Plastics. Congressman Ryan meets with Tim and Steve, and then tours the facility, meets with the management team and holds a town hall meeting with all Allied employees.

October 2015 Allied celebrates 20 years in business

December 2015 Allied convert’s original employee lunchroom into offices for Human Resources and engineering and operations directors.

December 2015 Allied installs MAAC 11 a 4’x 6’ single shuttle thermoformer

May 2014 We install MAAC 10 a 7’x9’ three station rotary thermoformer

June 2014 We construct the storm water retention pond and new employee parking lot at the Twin Lakes campus.

June 30 2014 New construction kicks off for the 54,462 sq. ft. building addition.

June 2014 We excavate and create and pave the outdoor storage area in Genoa City adjacent to the distribution center

July 2014 We install KMT number 3 dual robotic trim cell

December 2014 We get occupancy on new east building addition 54,462 sq. ft., building addition

March 2013 We constructed the “Production Control” offices located between the 1999 and 2006 building addition. This much needed space houses production scheduling and support personnel.

September 2013 Allied purchases Romer portable CMM machine with 3D scanning capabilities

September 2013 We built new offices and employee lunchroom at the Genoa City location

December 2013 We purchase and install MAAC 9, a 3’ x 4’ single shuttle twin sheet pressure former.

July 2012 Allied Installs KMT # 2 robotic trim cell, this cell is a dual robot 8’x8’ cell

August 2012 took delivery of our CNC #7 a new DMS (Diversified Machining System) 5×10 twin table 5-axis CNC router

October 2012 Allied Plastics, Inc. is notified that it is the recipient of “Business of the Year” From KABA Kenosha Area Business Alliance and KA Kenosha Area Chamber of Commerce.

October 2012 Construction of a 12,750sq ft cold storage building starts north of the existing facility, this space will be used for raw material storage

October 2012 Allied installs MAAC #8 an 8’ x 14’ four station twin sheet rotary thermoformer.

February 2011 Allied leases 10,000 sq. ft. of storage space in Burlington, WI. Allied moves aluminum mold storage to this location. This gave us additional storage for WIP and Finished goods

June 2011 developed 2.9 acres of property to the north of the facility (former Village Property) that will be used for outdoor storage.

November 2011 Allied purchases a 46,000 sq. ft. building in Genoa City that will become our new Distribution Center

November 2011 Allied is the recipient of the “Fast Five Award” presented by Kenosha County Chamber of Commerce and Kenosha Area Business Alliance.

April 2010 We install overhead crane system above number 7 former to help move large parts.

August 2010 We order our first Robotic Trim cell KMT Robotics

November 2010 We took delivery of our two brand new DMS (Diversified Machining System) 5-axis CNC routers.

Converted Tech Center into new Sales Showroom and Conference Room

July 2009: Allied participates in Twin Lakes Libertyfest Parade

February 2008 we installed a brand new 8.5’x12.5′ four station double oven, twin sheet pressure former by AVT which is known as # 7 machine.

November 2008 awarded Economic impact Award by Kenosha Area Chamber of Commerce & Kenosha Area Business Alliance

February 2007 Construction of new shipping office takes place

March 2007 Allied moves into the new building, which added another 18,800 sq ft. Also a 25’ wide enclosed ramp connecting all 3 buildings was built. After these additions, the total facility is now approx 100,000 sq ft.

June 2006 Allied works with the Village of Twin Lakes to shut down Industrial Drive between the 150 Holy Hill Rd and the 170 Holy Hill Rd buildings, referred to as Allied East and Allied West buildings. The proposal included Allied purchasing Twin Lakes Storage sheds that we located on Industrial Drive.

August 2006 The village shut down the road and construction started on a building addition between the “East and the West” buildings.

December 2006 Allied adds another 50,000 gallons of on site water storage to support our sprinkler system. This system utilized Cultec chambers which were installed just north of the existing concrete tank. This added capacity brought our total on site storage to 90,000 gallons.

Allied Plastics celebrated a decade of being in business.

August 2004 – We remodeled the office space and moved our sales and engineering departments to the new “Technology center” known as Allied East Building. This has allowed our sales, design and tooling departments to work closely together and gave us much needed office and floor space in the west bldg to continue our growth.

February 2003 – We installed a brand new 7’x9′ three station MAAC rotary which is known as # 6 machine to accommodate large parts and it also gave us the ability to run two dunnage trays side by side.

June 2003 – We evicted our tenants and remodeled the front half of the old Basset wheel bldg and moved former # 3 and CNC # 3 machine along with the pattern shop, mold finishing departments to this space.

March 2002: We became ISO 9001 certified for the first time.

We purchased the Basset Racing Wheel building located east of Allied Plastics. This gave us much needed warehouse space. We leased out approximately 12,000 sq ft of the 26,000 sq ft bldg.

In 2000 Allied Plastics installed a new twin table 5’x 10’ five axis CNC Router. (No pics of the install)

Additionally, to celebrate our 5th year in business, we hosted a company golf outing.

In 1999 we reached 2 milestones. We added on to our facility for the second time and purchased and installed a MAAC#5 (our first twin-sheet machine).

In 1998 we hosted our first ever Open House, we cleared space for our New Tool Room, and construction began on our New Office Spaces.

Allied Plastics broke ground on our first addition. It would be a 22,500 sq. ft. addition to the existing 9,800 sq. ft. facility.

Allied Plastics expands by installing our second machine, a 5’x6′ 3-station Maac rotary.

Allied Plastics OPENS FOR BUSINESS!

We begin doing business with our first machine, a 5’x8′, 3-station Maac rotary thermoformer.