Full-Service Custom Plastic Sheet Extrusion Capabilities

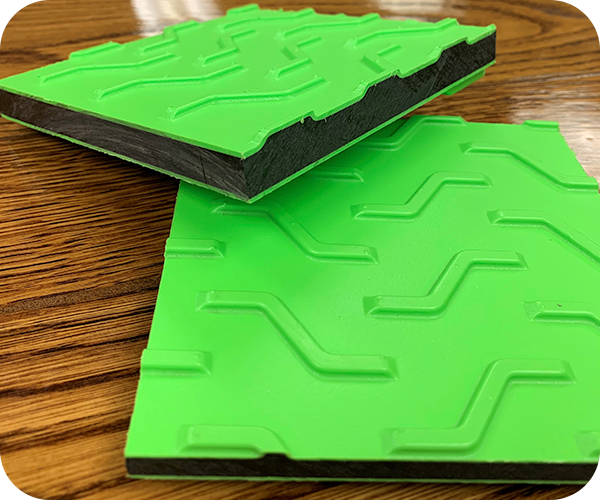

Allied Plastics is a full-service Custom Sheet Extruder with sheet size capability up to 120” wide x 200” long and .060” to .550” thick. Our team has experience in Extruded Sheets in a wide variety of materials, such as Polyethylene, TPO, ABS, Styrene, and more. Allied’s extruded sheets come in a variety of textures from Smooth, Haircell or Levant. Allied’s extrusion department can also add Film to the Sheets and cap sheets with our Co-Extrusion processing.

Co-Extrusion Capping is the ability to add multi-layer materials together to create a single extruded sheet. Example: One color over another color, Acrylic over ABS, Crystal Styrene over Styrene. Also the ability to add the film to the sheets, Example: Korad, CET Films, Poly-Stripe, Printed-Mono Poly, Printed-Mono Acrylic films. Ask us about the options of Co-Extruded Capping and adding film to extruded sheets.

Allied Plastics offers State of the art Custom Color capabilities with the most accurate blending equipment, plus the ability to add other ingredients such as UV stabilization and impact modifiers. We have a Full lab on site for analysis of the extruded sheets including but not limited to Impact, Melt, Color and many more. We also recycle plastic back into the process to remain green.

Custom Sheet Extrusion Material Options

- HDPE (Also available in a special anti-static grade that helps protect against static discharge)

- HMWPE

- TPO

- ABS

- Polystyrene

- Polypropylene

Ability to Add Film to the Extruded Sheets

- Korad

- CET Films

- Poly Stripe

- Printed-Mono Poly, Printed-Mono Acrylic films

- Printed-Mono Acrylic films

Textures Added to Extruded Sheets

- Smooth

- Haircell

- Levant