Vacuum Formed Plastic Vs. Injection Molding: Selecting the Right Process for Your Project

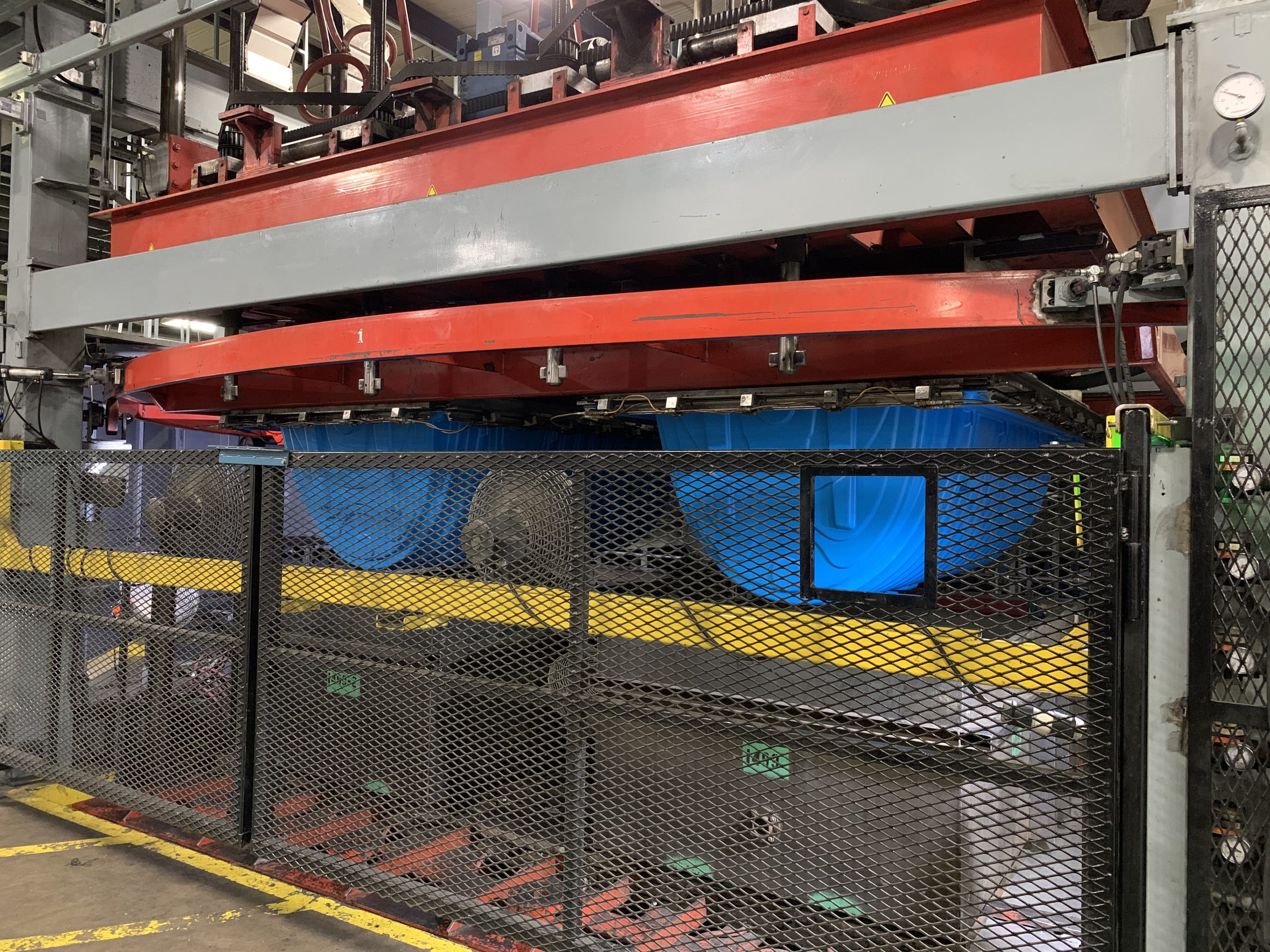

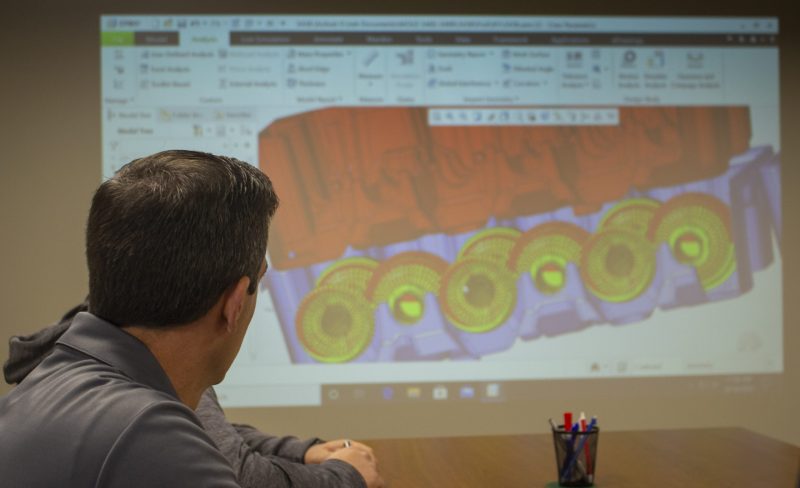

How to Choose Between Manufacturing Methods for Optimal Results Manufacturers face critical decisions when selecting plastic manufacturing processes for their components. Two of the most common methods — vacuum forming (thermoforming) and injection molding — offer distinct advantages depending on project requirements. As a premier heavy-gauge thermoforming company with over 30 years of experience, Allied … Read more