Advanced Thermoforming Solutions for Modern Vehicle Components

Modern automotive manufacturing demands precision, consistency, and reliability at every step. Plastic components play an increasingly crucial role in vehicle design and production, from interior panels to functional exterior parts. Advanced plastic manufacturing technology has become essential to meeting these rigorous requirements while maintaining efficiency and quality.

Allied Plastics stands at the forefront of automotive plastic manufacturing, combining cutting-edge technology with decades of industry expertise. Our comprehensive suite of manufacturing capabilities delivers the precision and reliability that automotive OEMs demand. Today we’re reviewing some of our technological investments for this sector.

Want to learn more about technology investment, thermoforming, or other facets of our manufacturing expertise? Reach out to our experts today.

5 Areas of Plastic Manufacturing Technology That Drive Success

1. Critical Manufacturing Technologies

The foundation of automotive-grade plastic manufacturing lies in advanced production equipment. Large-format thermoforming machines, capable of handling parts up to 9′ x 14′, provide the capacity needed for automotive components of any size. At Allied Plastics, this capability is enhanced by 12 5-axis CNC machines and five robotic trimming systems that ensure precise, repeatable finishing of complex geometries.

These automated systems work in concert to maintain tight tolerances and consistent quality across production runs. The integration of robotics and CNC technology not only improves precision but also increases production efficiency — a critical factor in meeting automotive industry demands.

2. Material Processing Capabilities

Success in automotive manufacturing requires expertise in processing a wide range of materials. Modern thermoforming technology enables the use of automotive-grade materials including:

- High-impact ABS for interior components

- Weather-resistant TPO for exterior applications

- Durable HDPE for structural elements

- Specialized materials for specific performance requirements

At Allied Plastics, our advanced sheet extrusion technology provides control over material thickness from .060″ to .550″, while co-extrusion capabilities allow for multi-layer constructions that meet specific performance requirements. Surface finish options range from smooth to textured, meeting both functional and aesthetic demands.

3. Quality Assurance Technology

Automotive manufacturing requires sophisticated quality control systems. Modern inspection technology includes:

- Automated dimensional verification

- Material property testing

- Surface quality inspection

- Process parameter monitoring

- Complete traceability systems

These systems ensure that every component meets exact specifications while providing the documentation required by automotive OEMs.

4. Production Efficiency Systems

Meeting automotive industry demands requires more than just manufacturing capability. Advanced production management systems enable:

- Just-in-time manufacturing

- Real-time inventory tracking

- Electronic data interchange

- Automated shipping notifications

- Supply chain integration

These technologies ensure reliable delivery while optimizing inventory levels and reducing costs.

5. Design and Engineering Technology

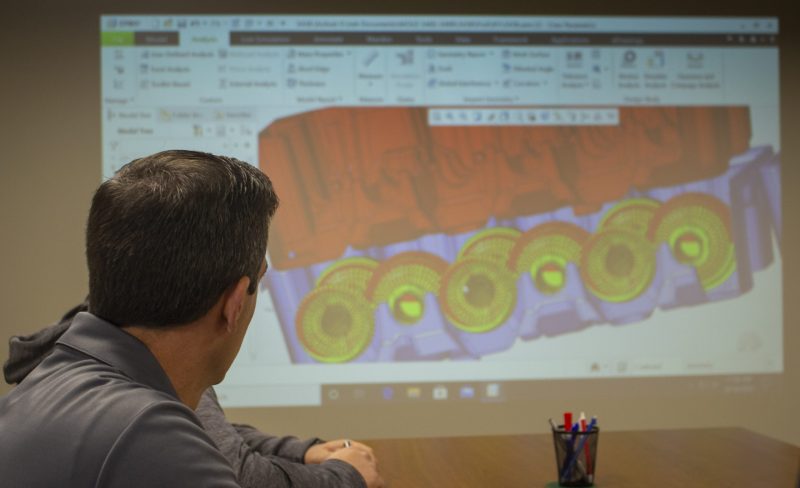

Modern automotive manufacturing begins with sophisticated design and engineering tools. Advanced CAD systems, simulation software, and prototyping capabilities ensure that components are optimized before production begins. This technology-driven approach reduces development time while ensuring manufacturability.

Work With Allied for the Best in Plastic Manufacturing Technology

Allied Plastics leverages these advanced technologies to deliver superior results for automotive manufacturers. Our state-of-the-art facility in Twin Lakes, Wisconsin, combines cutting-edge equipment with proven expertise in automotive plastic manufacturing. From concept through production, we provide the technological capabilities and industry knowledge needed to meet demanding automotive requirements.

With over three decades of experience serving the automotive industry, Allied Plastics understands the critical role that advanced manufacturing technology plays in meeting OEM requirements. Our continued investment in cutting-edge equipment and processes ensures that we remain at the forefront of automotive plastic manufacturing, ready to meet the evolving needs of the industry.

Whether you’re developing new components or looking to optimize existing ones, Allied Plastics provides the technological capabilities and expertise needed to ensure success in automotive manufacturing. Contact our team to learn how our advanced plastic manufacturing technology can support your automotive applications.